The Future is Castellated©

We are AddWood, an innovator and provider of solutions throughout the wood construction value chain, from sawmill to construction site, and we believe the future of timber frame building is Castellated©.

About Us

Andrew Dewberry

Co-founder, Inventor & Technical Director

Andrew founded AddWood to realise his solutions in the wood construction value chain. An architect by training and serial inventor in the construction space, Andrew identified a game-changing opportunity. He has since created a lumber product able to revolutionise both lumber production and wood construction; and laying the groundwork for AddWood’s further planned innovations.

Melissa Grant

Co-founder & Business Director

Melissa brings an international background in business transformation and operational delivery to AddWood and is focused on growing the business to deliver maximum value to clients in the wood construction value chain. Her experience spans industry and management consulting in North America, Asia and Scandinavia including project delivery in wood product manufacturing, supply chain & logistics optimisation and consumer data strategy.

Our Solutions

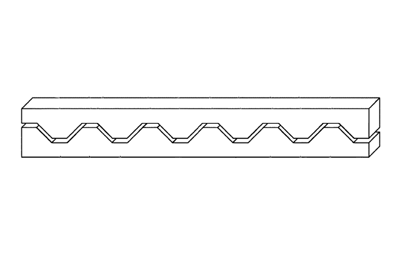

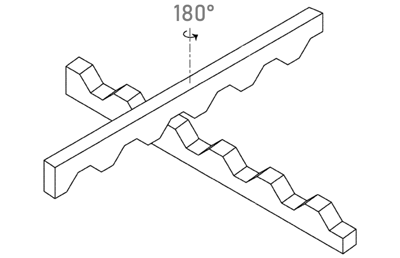

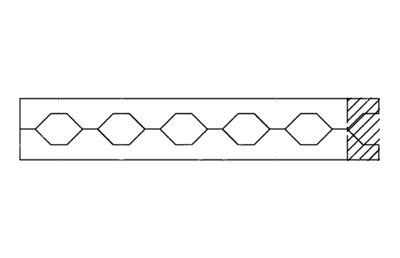

Our primary product is Castellated© lumber. It is produced by segmenting a rough-cut unit with a Castellated© cut, rotating the segments, then reassembling, gluing and pressing them before kiln drying. The Castellation© steps can be inserted into the traditional dimensional lumber production process between green sorting and kiln drying.

Segmenting by Castellated© cut

Rotation

Reassembly, gluing & pressing

Of the many applications for Castellated© lumber, replacing dimensional lumber used in framing is a stand-out. Castellated© lumber can transform the construction process: It eliminates rough-trades installation core-drilling owing to its intrinsic midline holes, enhancing accuracy in the construction process and maintaining a cleaner site. Intrinsic handholds and lighter weight facilitate easy handling and a reduction in load-bearing for construction team members. Overall, timber framing in Castellated© lumber unlocks shorter construction lead times.

Further up the wood construction value chain, Castellated© lumber provides yield improvement, energy savings in kiln drying time reduction, minimal processing waste, up-graded output and a lighter freight-friendly premium product, all of which can contribute positively to sawmill profitability.

Castellated© lumber is just the beginning for AddWood…

Get in Touch

This contact form is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.